|

Jinan YZH Machinery Equipment Co., Ltd

|

Stationary Rock Breaker Boom System

| Price: | 60000.0 USD |

| Payment Terms: | T/T,L/C,WU,Paypal,Money Gram |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

YZH brand rock breaker solutions are complete functional packages for rock breaking in the primary crushing stage. The breaker booms and hammers are e

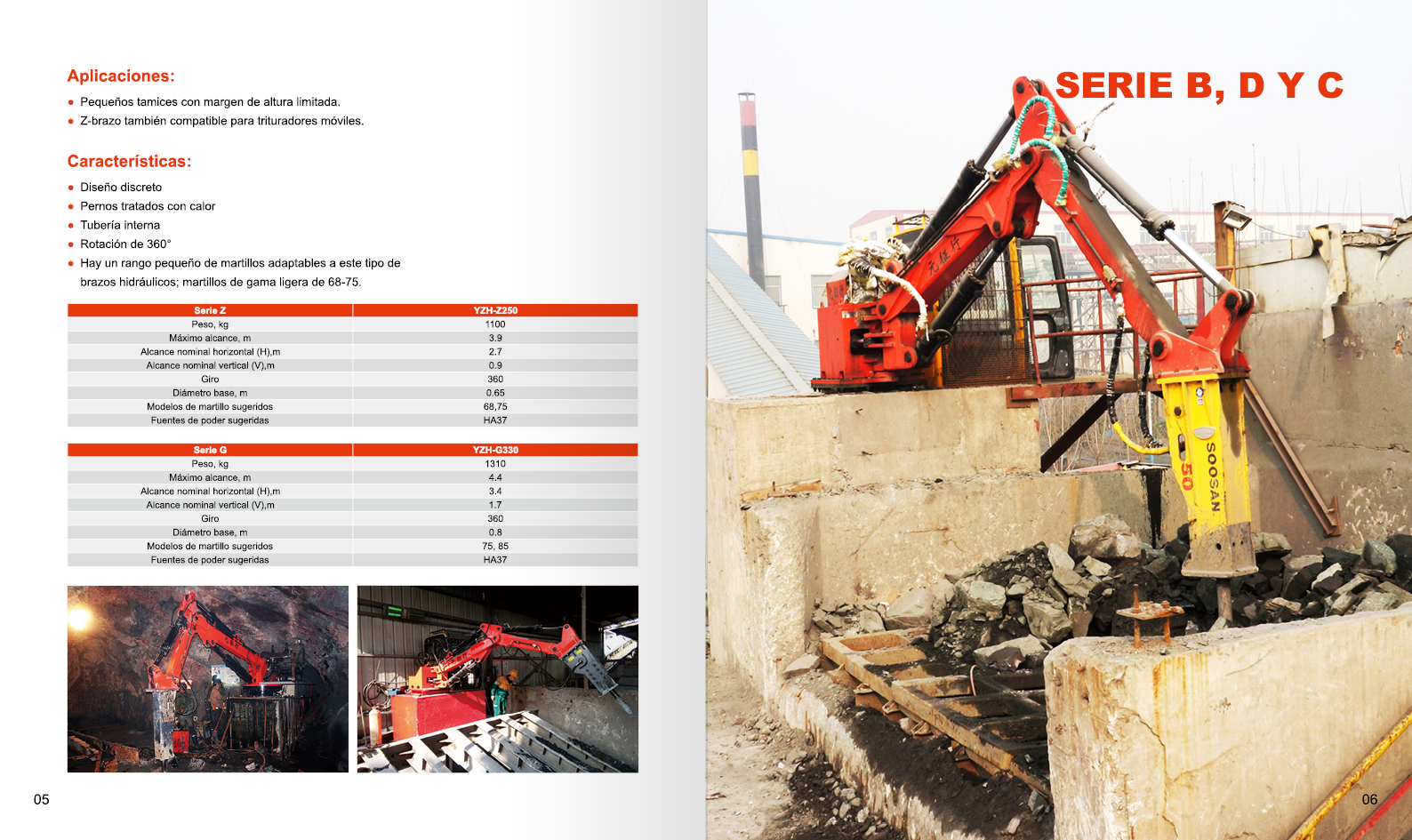

Stationary Rock Breaker Boom System

YZH brand rock breaker solutions are complete functional packages for rock breaking in the primary crushing stage. The breaker booms and hammers are engineered to meet the requirements set by rough primary crushing applications. These packages are optimized to work together and support primary crushers, ensuring the best productivity of the whole primary crushing station.

Rock breaker for primary crushing applications:

YZH brand rock breaker is a solution for primary crushing applications. They are most commonly used to break oversized rocks on top of the crusher cavity, to move single rocks which are stuck somewhere or to break build-ups caused by multiple coarse but not necessarily oversized rocks. Rock breakers are typically used to support the primary crusher, either jaw crushers or primary gyratories. Rock breakers can also be used to crush oversized boulders on top of the grids or grizzlies or to assist material flow in chute works or other possible challenging places in crushing processes.

Breaker Booms Features

YZH brand rock breakers consist of following components: breaker boom, impact hammer, hydraulic power unit and radio remote control. YZH brand rock breakers are engineered and built tough for the demanding primary crushing applications to meet the same requirements as the crushers.

YZH brand rock breakers are operated by a remote-control unit. Same unit can be used as a radio remote unit or as a cable remote control unit depending on customer preference.

The remote-controlled boom and hammer with the radio remote control, which is part of standard scope of delivery, means that the boom and hammer can be operated from a location that gives the operator unlimited visibility into the area where the rocks are moved or broken.

Breaker Booms Benefits:

Long-term plant production is significantly improved when the primary station is equipped with a rock breaker solution. Downtime due to build-ups and blockages can be easily cut to a minimum. This ensures a steady material flow through the primary station to the next process stages. The huge economic impact as a result of improved productivity means that the investment pay-back time is typically very short.

Each rock breaker is a complete optimized package which is dimensioned perfectly to operate smoothly as a package. Each package is optimized to support certain size jaw crusher or primary gyratory.